Ecosure Gloss & Undercoat

Superior formulations providing a 'best in class' finish

Ecosure water-based Gloss and Undercoat have been developed to deliver all of the advantages of water-based systems and achieve a professional finish normally associated with solvent-based variants, while being more environmentally friendly paints.

- Durable, quick drying with good opacity and adhesion

- 30% less embodied carbon when used as a system

- 78% less VOC content

- Unique nano-technology for a smoother, glossier finish

- Non yellowing

- Suitable for interior wood and metal

- Can contains 50% recycled material

- Spreading rate of up to 16m2

Unique ICI nano-technology

Unlike conventional water-based paints (traditional paints or eco paints) , Ecosure water-based Gloss and Undercoat utilise unique Dulux Trade nano-technology, which as well as offering improved flow, levelling and gloss, also offer an increased open time for improved application. The result is a noticeably superior finish.

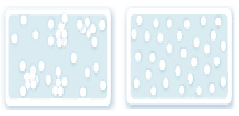

- Fig 1. New Ecosure water-based gloss and undercoat

- Fig 2. Conventional water-based gloss and undercoat

Improved particle distribution for improved gloss

As some water-based products dry, microscopic pigment particles can clump together, leading to an uneven finish. However Ecosure water-based Gloss and Undercoat have been formulated to improve pigment distribution, resulting in a more even, glossier finish.

-

The Ecosure range has been listed on the One Planet Product website. These paints have been assessed against the One Planet living principles which include carbon emissions, waste, transportation and water usage. This listing follows a detailed environmental scrutiny of both the products and the business as a supplier.

*PBW, Magnolia & some Light Base colours only. No organic volatile materials, such as solvents are added in the manufacture of this paint. However some of the raw materials that we use can contain traces of volatile components which is why this figure can never really be absolutely zero. Bases have 29% less solvent than standard Vinyl Matt formulations. **Compared with Dulux Trade Vinyl Matt (2007 formulation).

# Kettle typical rating = 3kW; time taken to boil for one cup = 30s; hence, energy used = 90 kWs or 0.025 kWh. UK Grid Rolling Average (2006) of CO2 per kWh = 0.54 KgCO2/kWh (source Defra Conversion Factors). Hence, CO2 per kettle boil = 13.5g